Siemens PLC Classification

Jun 08, 2023

Programmable controllers are generated by the needs of modern production, and the classification of programmable controllers must also meet the needs of modern production.

Generally speaking, programmable controllers can be classified from three perspectives. One is to classify based on the control scale of programmable controllers, the second is to classify based on the performance level of programmable controllers, and the third is to classify based on the structural characteristics of programmable controllers.

Folding control scale

It can be divided into mainframe, mid size, and small size machines.

Mini computer: The control points of a mini computer are generally within 256 points, suitable for single machine control or small system control.

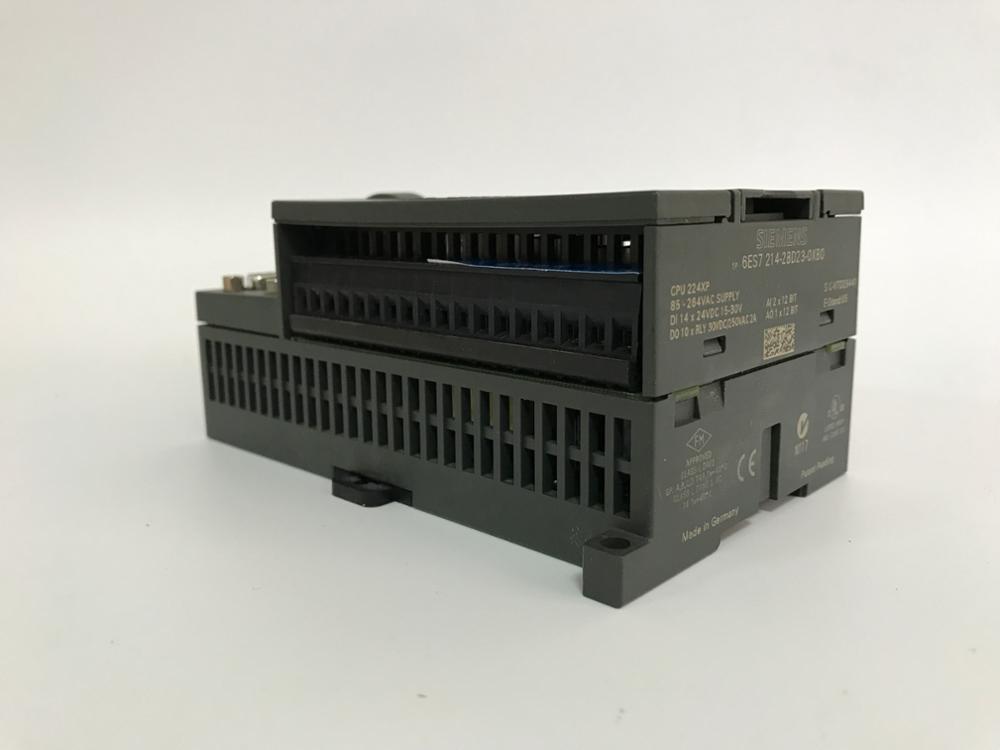

Siemens mini machines have S7-200: processing speed of 0.8~1.2ms; Memory 2k; 248 digital points; Analog quantity 35 channels.

Medium size machine: The control points of a medium size machine are generally not greater than 2048 points, which can be used for direct control of equipment and monitoring of multiple lower level programmable controllers. It is suitable for medium or large control systems.

Siemens mid size machines have S7-300: processing speed of 0.8~1.2ms; Memory 2k; 1024 digital points; Analog quantity 128 channels; Network PROFIBUS; Industrial Ethernet; MPI.

Mainframe: The control point of a mainframe is generally greater than 2048 points, which can not only complete complex arithmetic operations but also perform complex matrix operations. It can not only be used for direct control of devices, but also for monitoring multiple lower level programmable controllers.

Siemens mainframes have S7-1500 and S7-400: processing speed of 0.3ms/1k words;

Memory 512k; I/O point 12672;

Folding control performance

It can be divided into high-end machines, mid-range machines, and low-end machines.

Low-end machine

This type of programmable controller has basic control functions and general computing power. The working speed is relatively low, and the number of input and output modules that can be carried is relatively small.

For example, the S7-200 produced by SIEMENS in Germany belongs to this category.

Mid range machine

This type of programmable controller has strong control functions and computing power. It can not only complete general logic operations, but also complete more complex Trigonometric functions, exponent and PID operations. The working speed is relatively fast, and the number of input and output modules that can be carried is also quite large, and there are also many types of input and output modules.

For example, the S7-300 produced by SIEMENS in Germany belongs to this category.

High end machine

This type of programmable controller has powerful control functions and computing power. It can not only perform logic operation, Trigonometric functions operation, exponential operation and PID operation, but also perform complex matrix operation. The working speed is very fast, and there are a large number of input and output modules that can be carried. The types of input and output modules are also very comprehensive. This type of programmable controller can complete large-scale control tasks. Generally used as the main station in networking.

For example, the S7-400 produced by SIEMENS in Germany belongs to this category.

Folding structure

Integral

The integrated programmable controller integrates the power supply, CPU, memory, and I/O system into one unit, which is called the basic unit. A basic unit is a complete PLC.

When the control points do not meet the requirements, an expansion unit can be connected again. The characteristics of the integrated structure are very compact, small size, low cost, and convenient installation.

Combined

A modular programmable controller divides the various components of a PLC system into several modules according to their functions, such as CPU module, input module, output module, power module, and so on. The functions of each module are relatively simple, but the types of modules are increasingly rich. For example, some programmable controllers, in addition to basic I/O modules, also have some special functional modules, such as temperature detection module, position detection module, PID control module, communication module, and so on. The characteristic of a modular PLC is that the CPU, input, and output are all independent modules. Unified module size, neat installation, free selection of I/O points, convenient installation, debugging, expansion, and maintenance.

Stacked type

The stacked structure combines the advantages of compact, small size, and easy installation of the overall structure, as well as the flexible and neat installation of the I/O points in the combined structure. It is also composed of combinations of various units. Its characteristic is that the CPU is an independent basic unit (composed of the CPU and certain I/O points), and other I/O modules are expansion units. During installation, there is no need for a substrate, only cables are used for connection between units, and each unit can be stacked one by one. Enable the system to achieve flexible configuration and compact size.

Detailed introduction

1. SIMATIC S7-200 PLC S7-200 PLC is a miniaturized PLC that is suitable for automatic detection, monitoring, and control in various industries and occasions. The powerful functions of the S7-200 PLC enable it to achieve complex control functions whether running alone or connected to a network. The S7-200 PLC can provide 4 different basic models and 8 types of CPUs to choose from.

2. SIMATIC S7-300 PLC S7-300 is a modular small PLC system that can meet medium performance requirements for applications. Various individual

The modules can be widely combined to form systems with different requirements. Compared with the S7-200 PLC, the S7-300 PLC adopts a modular structure and has high speed (0.6~0.1 μ s) Command operation speed of; Floating-point arithmetic arithmetic can effectively realize more complex arithmetic operations; A software tool with a standard user interface that allows users to easily assign parameters to all modules; Convenient human-machine interface services have been integrated into the S7-300 operating system, greatly reducing the programming requirements for human-machine dialogue. The SIMATIC Human Machine Interface (HMI) obtains data from the S7-300, which transmits it at a user specified refresh rate. The S7-300 operating system automatically handles data transmission; The intelligent diagnostic system of CPU continuously monitors whether the system functions normally, records errors and special system events (such as timeout, module replacement, etc.); Multi level password protection can enable users to highly and effectively protect their technical secrets, preventing unauthorized copying and modification; The S7-300 PLC is equipped with an operation mode selection switch, which can be removed like a key. When the key is removed, the operation mode cannot be changed, which can prevent illegal deletion or rewriting of user programs. Equipped with powerful communication functions, the S7-300 PLC can provide communication configuration functions through the user interface of the programming software Step 7, making configuration very easy and simple. S7-300 PLC has a variety of different communication interfaces, and connects AS-I bus interface and Industrial Ethernet bus system through a variety of communication processors; The serial communication processor is used to connect point-to-point communication systems; Multi Point Interface (MPI) is integrated into the CPU and used to simultaneously connect programmers, PCs, human-machine interface systems, and other SIMATIC S7/M7/C7 automation control systems.

3. SIMATIC S7-400 PLC S7-400 PLC is a programmable controller used in the medium to high performance range. The S7-400 PLC adopts a modular fanless design, which is reliable and durable. At the same time, it can choose multiple levels of CPUs (with gradually upgraded functions) and is equipped with templates for various universal functions, allowing users to combine them into different specialized systems according to their needs. When the scale of the control system is expanded or upgraded, as long as some templates are added appropriately, the system can be upgraded and fully meet the needs.